Description

The Tajima TMEZ-KC Embroidery Machine

“TMEZ-KC” Multi-head Cylinder Type Flagship Model

The TMEZ-KC series multi-head cylinder type embroidery machines are equipped with Tajima’s latest and most advanced technologies. It is suited for logo and emblem embroidery on products such as sports uniforms and hats in small to medium quantities. The i-TM and DCP allow even embroidery beginners to work on any material, at high speed and with stable quality.

The TMEZ-KC is Available in 4, 6 and 8 head – 15 needles

High quality, stable stitches with “i-TM” and “DCP

The need to adjust the upper thread tension according to the stitch, design, or material, as is done by skilled operators on conventional embroidery machines, is no longer necessary.

The reason is that Tajima’s Digitally Controlled Presser foot (DCP) measures fabric thickness with each stitch, and its AI technology, Intelligent Thread Management (i-TM), automatically supplies the right amount of upper thread for different fabric thicknesses and stitches in just 0.05 seconds. In addition, DCP suppresses fluttering and enables stable sewing.

Point 1: Stable production of top-quality embroidery

Even if the item to be embroidered or thread type changes frequently, such as an in-store order, the embroidery machine will always provide the best possible stitches without having to change settings.

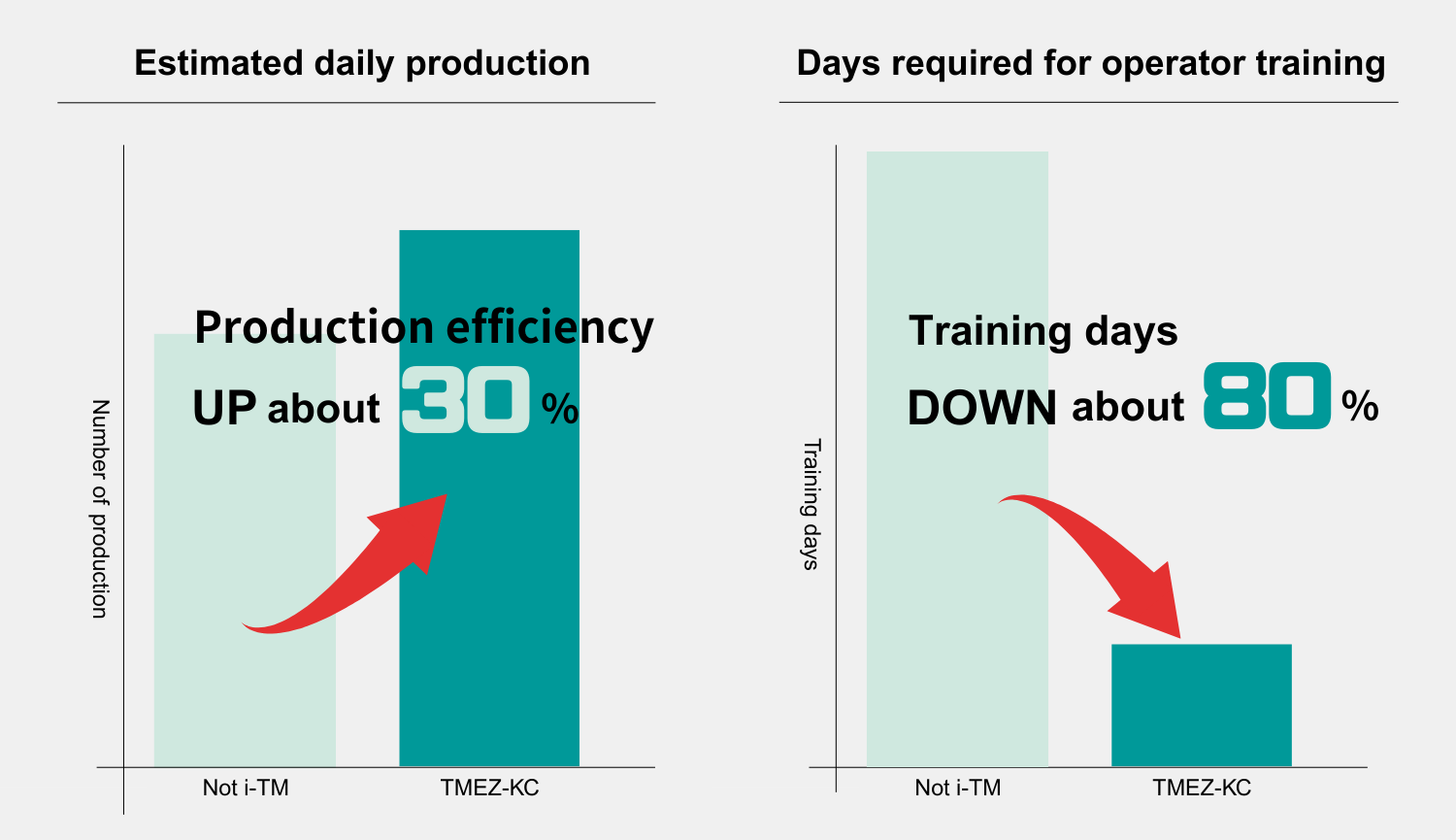

Point 2: Significant productivity improvements

The time required for trial sewing and adjustment can be reduced, and the speed can be increased with less worry of thread breakage, resulting in an estimated 30% reduction in processing time (compared to conventional machines). Less adjustment work allows multiple embroidery machines to be controlled at the same time, increasing production per operator.

Point 3: Minimize quality defects

The DCP reduces fabric fluttering, resulting in fewer press marks and thread trimming errors, and thus fewer defective pieces. Manual adjustment for delicate fabrics such as velvet and enamelled material reduces the risk of fabric press marks.

Point 4: Operator early empowerment

Even in a shift-based factory, where operators are frequently replaced, embroidery can always be performed with consistent quality, regardless of the operator’s skill level. Operators become a competitive force at an early stage because of the small amount of time required to acquire skills.

Contributes to production efficiency and operator training

*A man-hour required for upper thread adjustment is assumed to be 0, since i-TM automatically supplies the appropriate amount of upper thread for different fabric thicknesses and stitches.

*Productivity calculations assume 10,000 stitches on an 8-head embroidery machine.

*Training time can be significantly reduced because there is no need to adjust upper thread tension for different materials.

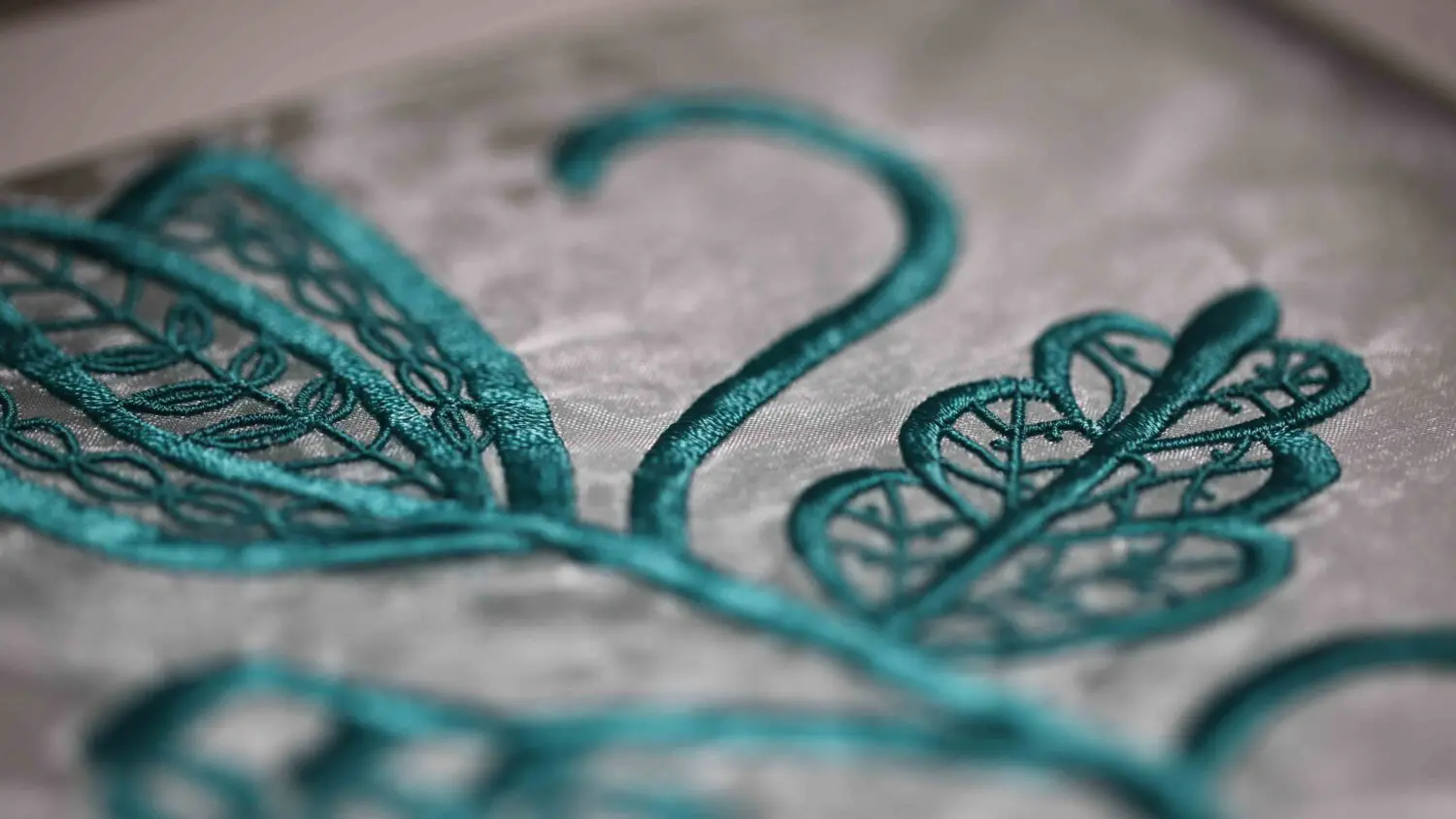

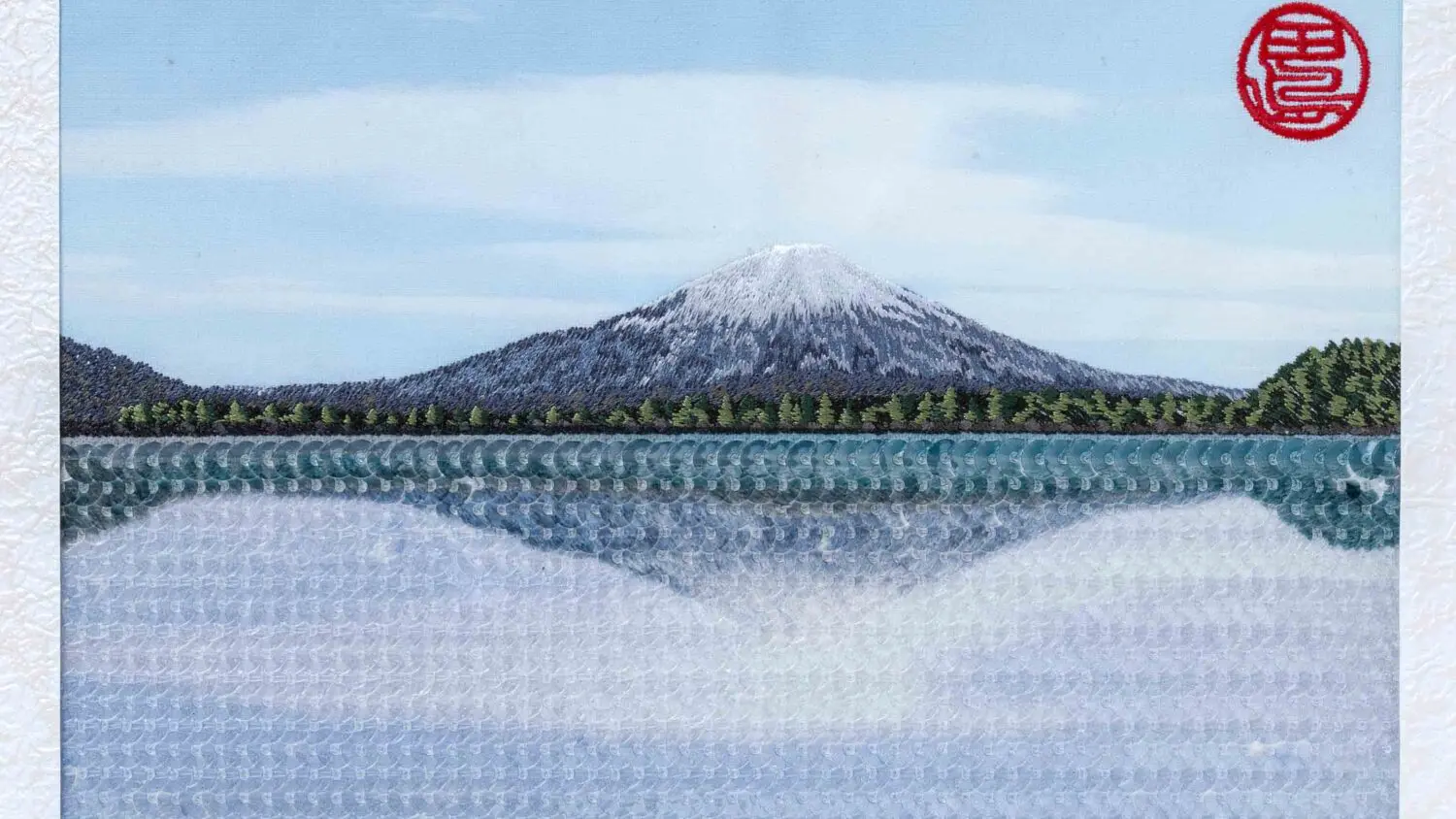

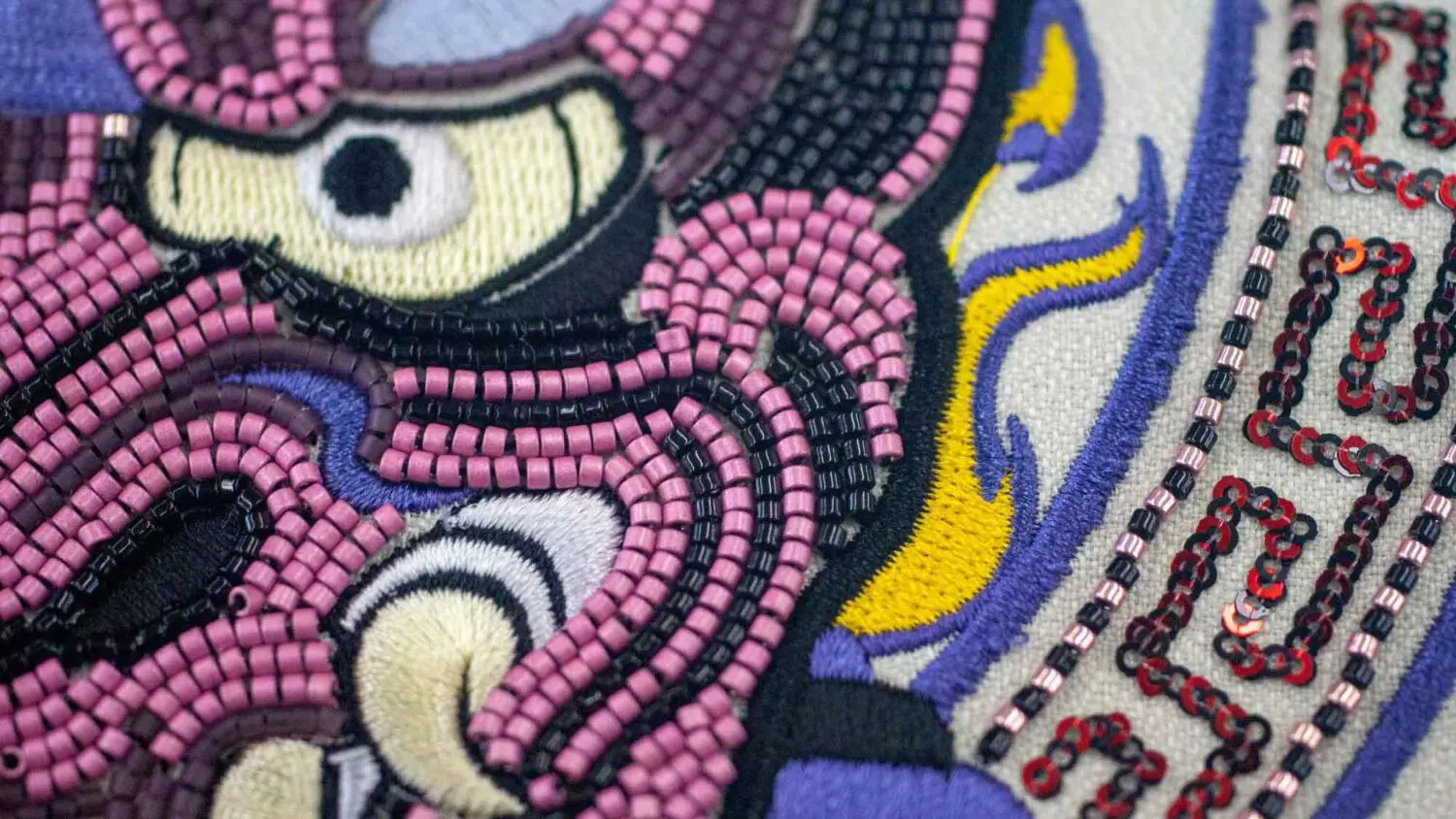

Tajima’s quality recognized by leading brands

It is used by leading brands and fashion houses. They yield a beautiful finish, regardless of whether you are using a satin stitch, a running stitch, or a fill stitch. What’s more, a variety of options for sequins and beads enables additional forms of expression. Beautiful and exquisite embroidery with multi-head technology in which all heads are synchronized.

The TMEZ-KC is Suitable for any finished product, regardless of the item

Fast and clean cap embroidery

Large-diameter shaft makes it easy for anyone to install the cap frame. Three-point locking between the drive ring and cap frame provides more stable fixation, less needle breakage and pattern misalignment, and operation at a maximum speed of 1,000 rpm.

Reinforced arm supports heavy items

Three times stronger than traditional embroidery machine arms, they are also more suitable for embroidery on jackets and other heavy items.

Slim cylinder beds for small goods

The smaller diameter of the cylinder bed and the smaller bobbin cover allows for easy embroidery on tubular finished products such as sleeves and pockets.

User-Friendly Design

In addition to i-TM and DCP, the machine offers a wide variety of operator-friendly functions and options. This reduces operator workload while ensuring high quality embroidery production and smooth machine operation.

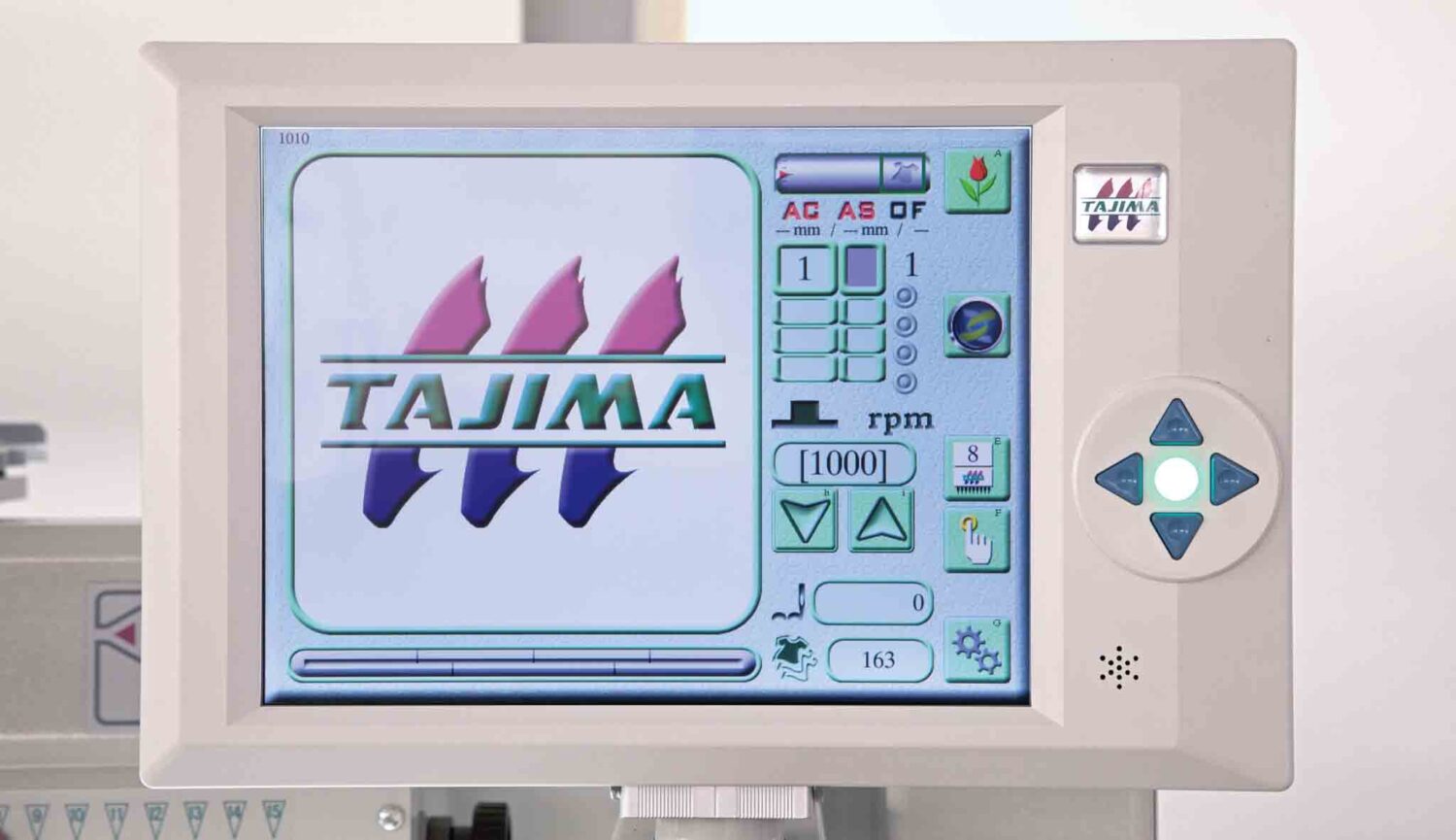

12.1-inch touch panel

The large 12.1-inch operation panel—one of the largest in the industry—features convenient icons and allows you to switch the language used for operating the machine.

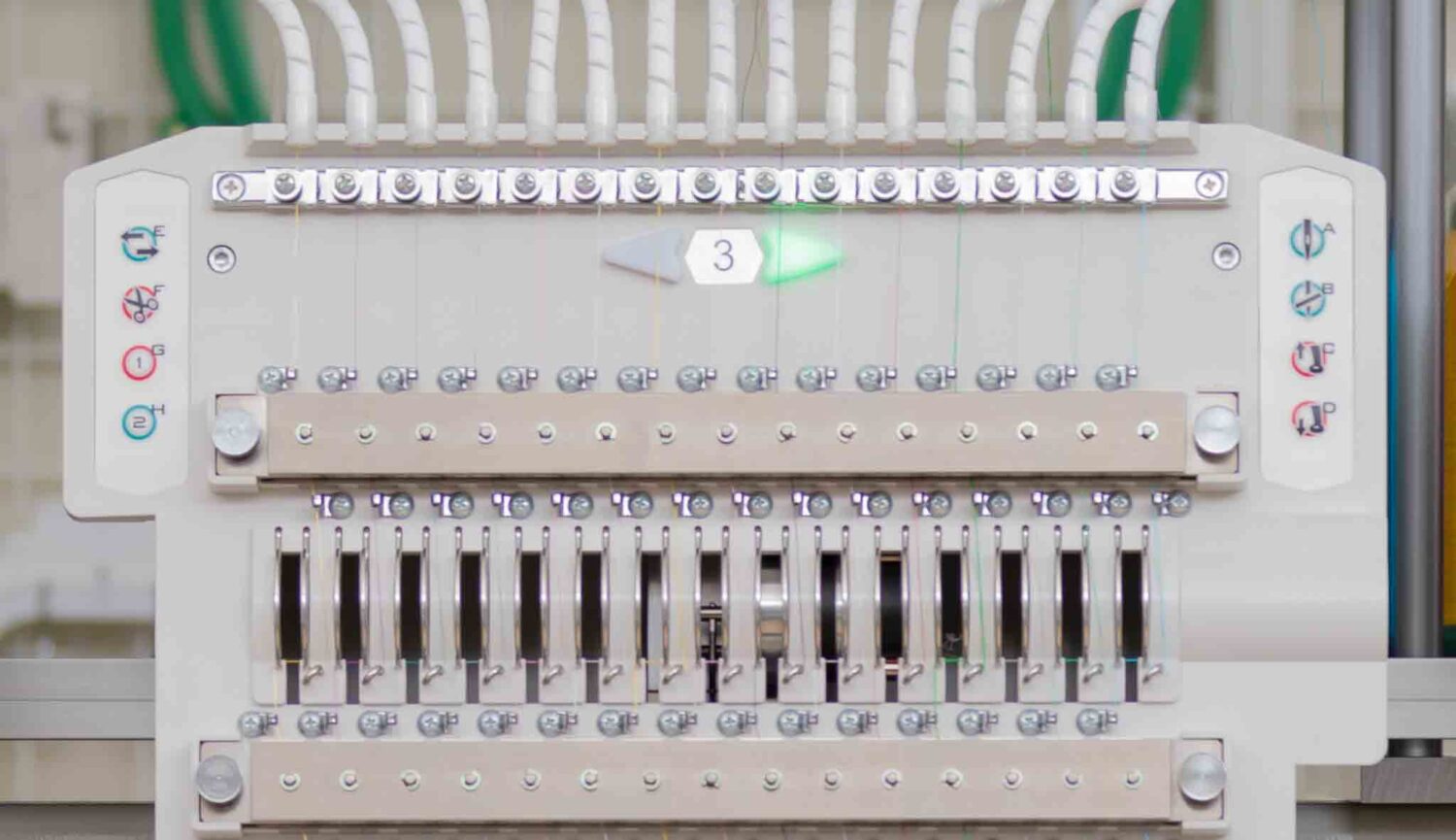

Direct Command Switches

Located on the head, these operation switches provide control of the thread trim and other functions at each tension base for increased production efficiency.

New auto thread trimming device

Eliminating the picker makes exchanging bobbins easier. It also provides more stable trimming and a 40% improvement over conventional machines in shortening thread tails on the reverse side of the fabric.

Tajima’s Customer Support Services

Offer Personalized Embroidery Through E-Commerce and Stores

PulseID provides comprehensive support for embroidery personalization, from receiving in-store or online e-commerce orders to production and management. It saves labor and increases efficiency while helping enhance brand loyalty and advertising effectiveness.

Sales in 160 countries and regions around the world.

We have delivered machines to 160 countries and regions and have a worldwide service network. Replacing embroidery machines or starting a new embroidery business? We apply Tajima’s proprietary AI technology and software in helping resolve our customers’ business issues. Please feel free to contact us through the CONTACT form.