Tajima TMAR VC Large Multi Head Embroidery Machine

Login to see pricesThe NEW flagship model with unsurpassed flexibility.

The Newly released TMAR-VC has been designed exclusively for large production work, particularly for Cap and tubular embroidery applications.Giving you the highest quality embroidery machine with the latest of Tajimas renowned technology,It offers clients, ultimate quality, overwhelming durability and powerhouse performance. Its the only way to realize the utmost in embroidery quality !

Models Available in this Series.

- TMAR-V1212C-12 Head,

- 12 Needle R -V1215C-12Head 15 Needle

Description

TMAR -VC Series

The NEW flagship model with unsurpassed flexibility.

This Model is available in the following Configurations.

TMARK-VC1212 -12 Head,12 Needle.

TMARK – VC 1215-12 Head ,15 Needle.

The Newly released TMAR-VC has been designed exclusively for large production work, particularly for Cap and tubular embroidery applications.Giving you the highest quality embroidery machine with the latest of Tajimas renowned technology,It offers clients, ultimate quality, overwhelming durability and powerhouse performance. Its the only way to realize the utmost in embroidery quality !

NEW FEATURES

The NEW TMAR-VC is fully adjustable to create exquisite embroidery from Thick Fabrics such as,Caps with 3D Foam down to the Finest of Fabrics !

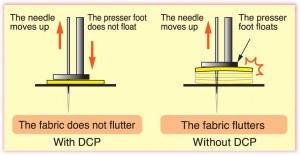

Equipped with the Tajima’s exclusive digitally -controlled presser foot system.

By digitally controlling fabric pressing,the DCP can be set to the thickness of the fabric so as not to over press the material causing shadows or damage .Also optimizing the timing of the fabric pressing, the DCP can suppress the “fluttering” of the embroidery material,beautifully finishing precision embroidery.

The DCP is very effective for hard to embroider materials like Leather,thick fabric,3D Foam with caps & stretchy fabric and quilting.

New developed slim cylinder bed & reinforced Cap frame.

The newly -designed Slim cylinder Bed,which has a downsized diameter compared to the conventional cylinders by about 12% ,has widened the range of application so as to cover tubular products,such as sleeves and pockets.

NEW reinforced Cap Frame.

The wide Cap frame also has been newly designed to upgrade the rigidity coinciding with the slim Cylinder Bed.This frame has enhanced the embroidery stability whereby increasing the rotational speed to 1000rpm and(900rpm for +4mm)

New improved Threading & Tension system.

For preserving stable quality,it is important to adjust the thread tension according to the thread, fabric and design you are using.The newly designed middle thread guide has halved the thread tension setting time for one needle compared with our conventional middle thread guide.You can set thread tension easier.Since the tension and stroke of the thread take up spring,which have been adjusted for each head,can now be

TOUCH-OPERATION DISPLAY

The touch-operation display is equipped with an intuitive, easy-to-use operation panel with easily identifiable icons.

The whole now has a high-capacity memory, which can store up to 40 million stitches or 650 designs, saving you

both time and money.

NEW- Direct command switch

Various operational switches and multi colour LED’s are located on each head.All of the main functions of the operational panel can be manipulated from each head,the working efficiency of the operators has been improved.Commonly used functions may be assigned to the custom switches.

NEW-Equipped with the FS Mode

The FS mode ,which has made the TFGN II series so sought after,can optimally tune the embroidery machine,and thereby reduce the burden on the yarn and improve the stability and quality of embroidery.Furthermore ,by using parts specially designed for the FS mode (option),even the difficult to embroider soft twist thread and thick thread can be embroidered.

New Reinforced Frame drive

This is accessible technology that offers you and your business pinpoint accuracy as well as advanced noise reduction.

Quick to change from cap to cylinder to tubular operation, the machine’s ultra strength tubular arms prevent distortion of embroidery, especially when sewing precise lettering and small designs. It’s revolutionary.

Easy Maintenance

By introducing the crank drive ,a new driving system ,into the embroidery machine head,

overwhelming durability has been realized.Also maintenance has become simpler,

and the lubricating frequency has been reduced to one twentieth.

Manage & Improve Productivity.

Embroidery data can be easily sent to the machines by connecting the embroidery software to a network. For name tag embroidery, Autograph is recommended as it simplifies the process. In addition to the DG/ML, it allows for the smoothest design data generation and transmission to the machine.

All Tajima embroidery machines have built in technology to load a design to the machine with the simple scan of a barcode.