Dekken T-Apparel

T-Apparel

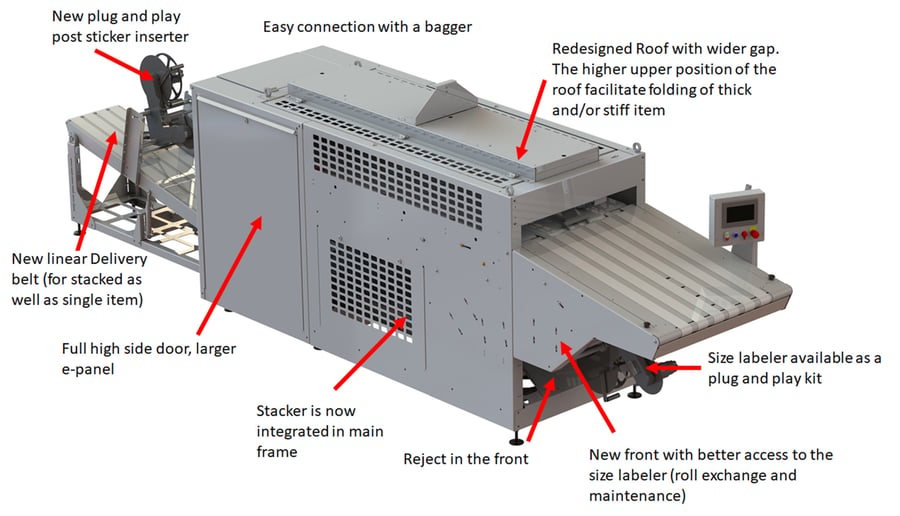

The T-Apparel is the most advanced, fully automatic clothing folding equipment offering Retail folding quality and the perfect solution for E-Commerce and Return handling.

The T-Apparel offers many different folding patterns and meets today’s requirements in the textile-industry.

The T-Apparel is able to handle all kinds of folding patterns. After being fed, the item enters the lateral folding section where air and position-controlled folding templates create the lateral folds. Each piece’s length is automatically measured to ensure exceptional quality. The adjustable roof position permits folding of thick, stiff, light, slippery textile, and dry-fit materials. The length of the lateral fold section accommodates all product sizes.

The internal conveying belts are cleverly designed to enable safe folding of products with hang-tags or sticky surfaces due to large print areas.

Video: https://vimeo.com/891567687?autoplay=1&muted=1&stream_id=Y2xpcHN8MjA4MzUzMDA0fGlkOmRlc2N8W10%3D

Video: https://vimeo.com/891567385?autoplay=1&muted=1&stream_id=Y2xpcHN8MjA4MzUzMDA0fGlkOmRlc2N8W10%3D

T-Apparel Possibilities

The T-Apparel folding machine is the most diverse folding machine on the market. It is therefore impossible to list all the products that can be folded.

Thanks to this advantage, the T-Apparel is an excellent solution not only for garment manufacturers, screen printers, embroiderers, but also for e-commerce companies that want to innovate their returns handling processes by fully automating the folding, packing and labelling tasks.

Stacking Function

Stack various amounts of textiles neatly in piles.

The conveyor belt, controlled pneumatically, enables easy switching between single item and stacked product output.

This allows for easy folding even of challenging materials such as polyester T-shirts that can be difficult to stack.

Video: https://vimeo.com/891567385

Size Labeler

Automatically applies pre-prinetd size labels before folding the products.

The flexibility of the label size and position is greatly attributed to the German-built label applicator utilized.

Video: https://vimeo.com/891567922

Post Labeller

Automatically applies pre-printed labels onto the product after folding.

The flexibility of the label size and position is greatly attributed to the German-built label applicator utilized.

The Post Labeller can either be placed on the conveyor of the T-Apparel or an external conveyor.

Video: https://vimeo.com/891567922

Cardboard Inserter

Automatically insert a cardboard stiffener prior to folding.

Thanks to the clever design of the T-Apparel, it is possible to use cardboard of different thicknesses and sizes.

Video: https://vimeo.com/891567887

Quickselect

For a diverse range of products that need to be fed into the machine mixed, the Quickselect is the easiest solution to have customized folding programs for every product while maintaining the full efficiency of the T-Apparel.

The layout, text, and images are customizable by the client using a simple drag-and-drop editor.

This visual interface dramatically reduces the time required for operator training.

No programming is required by the client.

Barcode Scanner

Change the folding program with a barcode scanner.

This reduces the chance of operator-induced errors resulting from incorrect program selection and improves overall productivity.

Video: https://vimeo.com/891567712

Remote Program Change

Update the folding program through Ethernet with your in-house IT systems.

This decreases the possibility of errors caused by operator selection of incorrect programs, thus enhancing overall productivity.

This option is recommended only for clients with programming capabilities as Dekken does not offer custom program development for integration with Production Management Systems.

Folding of hoodies

This video demonstrates size labeling, folding, packaging and post labeling of hoodies.

The conveyor belt connecting T-Apparel and T-Matic-5020 is an optional feature which can be used for packaging products that do not require folding.

The conveyor belt after T-Matic-5020 is crucial for the Post Labeller, while for a more space-saving approach, the Sato Label Printer & Applicator integrated system is an excellent solution.

Video: https://vimeo.com/891567922

Folding a large variety of garments

This video showcases the extensive selection of clothing that the T-Apparel can effortlessly fold.

No manual adjustments are required, as all the necessary modifications are made automatically once the program is changed.

This allows for the folding of mixed clothing without loss of productivity.

Video: https://vimeo.com/891567687

Folding of pants and trousers

This video showcases the folding and packaging of various types of pants, jeans, leggings, trousers, etc.

Video: https://vimeo.com/891567563

Folding of polyester products

Thanks to its advanced pressure control, the T-Apparel can fold hoodies and polyester garments simply by selecting the appropriate program.

Video: https://vimeo.com/891567548

| Maximum Product Dimensions | 160x100cm | 63x39in |

| Maximum Production per Hour | 1000 | 1000 |

| Maximum Production per 8 Hours | 8000 | 8000 |

| Air Pressure | 6 Bar | 87 PSI |

| Peak Air Consumption | 5 m³/h | 177 ft³ |

| Air Connection | ≥ Ø13mm | ≥ Ø1/2in |

| Machine Length | 3915mm | 154in |

| Machine Width | 1030mm | 40.5in |

| Machine Height | 1540mm | 60.5in |

| Machine Weight | 1050kg | 2315lb |

| Conveyor Length | 1565mm | 62in |

| Customizable Programs | 60 (240 Sub-Programs) | 60 (240 Sub-Programs) |